Equipment Specs

FARO Focus3D S150 Scan Kit

FARO Focus3D S150 Scan Kit

FARO Focus S150 S350 Scanner Spec Sheet

Check S150 or S350 Availability

The FARO Focus 3D laser scanner is a versatile and powerful tool with numerous applications in various industries. Here are a few examples of its uses:

- BIM Modeling: Building Information Modeling (BIM) is a process that involves creating a digital representation of a building or infrastructure project. The FARO Focus 3D scanner can capture detailed 3D point clouds of existing structures, allowing architects, engineers, and construction professionals to create accurate as-built models. These models can be used for renovation projects, clash detection, facility management, and more.

- Forensic Engineering: In forensic engineering investigations, precise and comprehensive data collection is crucial. The FARO Focus 3D scanner can capture detailed information about accident scenes, structural failures, or crime scenes. By creating an accurate 3D representation, investigators can analyze and reconstruct events, measure distances, extract dimensions, and perform virtual walkthroughs. This data can be used for analysis, simulations, and presentations in legal proceedings.

- Visual Effects Studios: The entertainment industry, particularly visual effects studios, can benefit from the FARO Focus 3D scanner. It can capture high-resolution 3D data of real-world objects, environments, or actors, which can be used as references or to create digital assets. This technology helps in integrating computer-generated elements seamlessly into live-action footage, improving the overall realism and quality of visual effects in movies, TV shows, and video games.

- Architecture and Construction: Architects, engineers, and construction professionals can use the FARO Focus 3D scanner to accurately capture and document existing structures, construction sites, or heritage buildings. This data can be used for design visualization, clash detection, quality control, and progress monitoring. The scanner allows for faster and more accurate measurements compared to traditional surveying methods, reducing errors and rework.

- Industrial Facilities: The scanner’s portability and versatility make it suitable for capturing complex industrial environments, such as factories, refineries, or power plants. It can generate detailed 3D models of machinery, piping, equipment, and entire facilities. This information is valuable for plant layout planning, facility management, maintenance, and retrofitting.

Overall, the FARO Focus 3D laser scanner provides precise, efficient, and highly detailed 3D data capture, enabling a wide range of applications across industries, including BIM modeling, forensic engineering, visual effects, architecture, construction, and industrial facilities. Its ability to rapidly capture accurate measurements and create realistic 3D models makes it an indispensable tool for professionals seeking to enhance their workflows and improve project outcomes.

General Information About the FARO Focus Laser Scanner

Intuitive touchscreen display

Control all scanner functions with a touch interface for unparalleled ease of use and control

Small and compact

With a size of only 9.5 x 8 x 4in and a weight of just 11lbs, the Focus 3D is the smallest 3D scanner ever built

Integrated Color Camera

Photorealistic 3D color scans due to an integrated color camera featuring an automatic 70 megapixels parallax-free color overlay

High-Performance Battery

Integrated lithium-ion battery provides up to five hours of battery life and can be charged during operation.

Data Management

All data is stored on a SD card enabling easy and secure transfer to a PC. Using SCENE WebShare, images can be shared on the internet.

Compass/GPS

An electronic compass is now included within the unit to associate directional data to your scans and facilitate the auto-registration process

WLAN (WiFi)

WLAN remote control permits you to start, stop, view or download scans at a distance

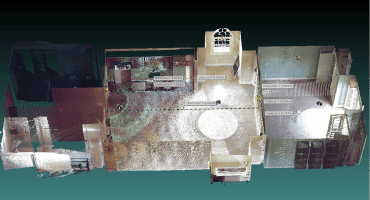

As you can see with the above example, each scanned image is represented in 2D and 3D HD color, but is also built in three dimension out of individual points. Each of these points, millions per view, are actually measuring points giving the user the ability to measure between any two objects or points in the almost 360 degree scanned view, down to the millimeter. With our ability to scan up to 976,000 points per second, ALSS can provide beautiful, highly accurate indoor or outdoor three-dimensional representations, measuring millions of points faster than conventional methods like Total Station or Photogrammetry measure just a few. This allows you to capture the scene quickly, then bring it back to the office and revisit the it and time again on your computer to review different lines of site or take a new set of measurements. For things like accident reconstruction, forensics and large scale disaster investigation, even visual effects studios, ALSS equipment and deliverable can make the difference between months of work, and hours of work. With traditional inspection methods, one or possibly multiple employees must enter potentially dangerous or sensitive environment to take digital photographs, and perform hand measurements resulting in a much less accurate representation of the scene than what ALSS can provide in a fraction of the time. In some cases, revisiting the original site in the original form is simply impossible, with the ALSS 3D full color laser scan data, it is not necessary to leave your computer at your desk. Long Range 3D Laser Scanning has many uses, and the number is growing exponentially every day as people learn what it’s all about. By quickly providing accurate measurements businesses are able to build more accurately, survey more quickly, and investigate more thoroughly and with more accuracy than ever before.

For more information about letting us serve your business,

email us at info@atlanticlaserscanning.com or

call us at (800) 955-3960.

Hesai RESEPI XT32 Lidar Kit

Inertial Labs_RESEPI XT32 Spec Sheet

Check Hesai RESEPI XT32 Availability

Survey drone LiDAR units, such as the RESEPI Hesai Xt32, Velodyne, Livox, R2A, R360, and Ouster scanners, offer several advantages over standard survey techniques. Here are some of their uses and benefits:

- Rapid Data Collection: Surveying large areas can be time-consuming and labor-intensive using traditional methods. LiDAR-equipped drones enable fast data acquisition by scanning large areas from above in a short period. This allows surveyors to cover more ground quickly and efficiently, reducing overall project timelines.

- High-Resolution 3D Data: LiDAR scanners on survey drones capture millions of points per second, resulting in highly detailed and accurate 3D data. This level of precision allows for precise measurements, enabling better analysis, modeling, and decision-making in various industries.

- Remote and Hazardous Area Mapping: Survey drones equipped with LiDAR can access remote or hazardous areas that are difficult or dangerous to reach on foot. This includes areas with rough terrain, dense vegetation, or limited accessibility. By collecting data from these challenging locations, surveyors can obtain comprehensive and accurate information without putting themselves at risk.

- Improved Data Quality: LiDAR technology eliminates many of the limitations and errors associated with traditional survey techniques. The high accuracy and density of the collected point cloud data result in detailed and reliable representations of the surveyed area. This enhanced data quality leads to more precise measurements, improved modeling, and better-informed decision-making.

- Multi-Sensor Integration: LiDAR units on survey drones can be integrated with other sensors, such as cameras and thermal imaging devices. This allows for simultaneous collection of additional data, such as high-resolution imagery, temperature readings, or multispectral data. By combining multiple data sources, surveyors can gain comprehensive insights and perform more in-depth analysis.

- Cost and Time Savings: LiDAR-equipped drones offer significant cost and time savings compared to traditional survey methods. They require fewer personnel and equipment, as well as less time in the field. Additionally, the rapid data acquisition and processing capabilities of LiDAR scanners enable quicker decision-making and reduced project timelines.

- Versatility and Scalability: LiDAR-equipped survey drones can be used in a wide range of industries and applications. They are suitable for topographic mapping, infrastructure inspections, construction monitoring, forestry management, mining, and more. Furthermore, the scalability of drone-based LiDAR technology allows for surveys of varying scales, from small sites to large-scale projects.

In summary, survey drone LiDAR units offer numerous advantages over standard survey techniques. They enable rapid data collection, provide high-resolution 3D data, access remote or hazardous areas, improve data quality, support multi-sensor integration, save costs and time, and offer versatility for various industries. Incorporating LiDAR technology into surveying workflows can enhance accuracy, efficiency, and overall project outcomes.

Creaform HandySCAN Black Elite 3D™

PrintableVersion_HandySCAN3D_Brochure_EN_HQ_27032019

Check Creaform Handyscan Black Elite Availability